What you need to know about Combined Heat and Power (CHP)

- Post Date

- 04 May 2022

- Read Time

- 3 minutes

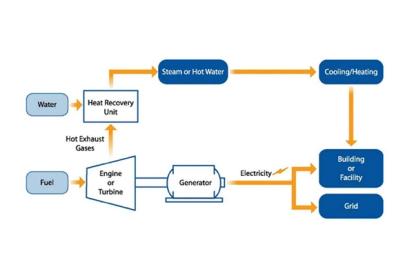

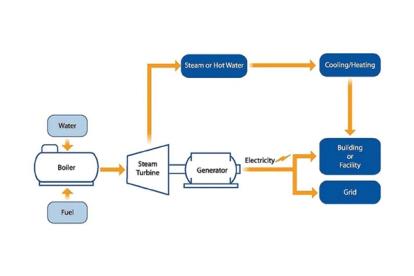

Combined Heat and Power (also known as co-generation) is an energy efficient technology that generates electricity locally and captures the heat that would otherwise be wasted to provide useful thermal energy—such as steam or hot water—that can be used for space heating, cooling, domestic hot water and industrial processes. CHP can be located at an individual facility or building or be a district energy or utility resource. CHP is typically located at facilities where there is a need for both electricity and thermal energy.

According to the US EPA, nearly two-thirds of the energy used by conventional electricity generation is wasted in the form of heat discharged to the atmosphere. Additional energy is wasted during the distribution of electricity to end users. By capturing and using heat that would otherwise be wasted, and by avoiding distribution losses, CHP can achieve efficiencies of over 80 percent, compared to 50 percent for typical technologies (i.e., conventional electricity generation and an on-site boiler). This means that facilities with combined heat and power systems in place are generally more efficient, more profitable, and better for the environment.

Two Common CHP System Configurations Are:

Combustion Turbine, or Reciprocating Engine, with Heat Recovery Unit, US EPA. 2018.

Steam Boiler with Steam Turbine, US EPA. 2018.

Lessons learned from Compliance Assessment

SLR has assisted numerous groups to prepare compliance and design assessments for environmental air quality, noise and vibration associated with the implementation of these systems. The main issue that has been occurring on a number of projects is legacy issues with older equipment, especially in the case of compliance with noise; for example, older or pre-existing HVAC equipment. SLR has worked with the proponent to determine solutions to help with these issues.

In Ontario, there are two different approval streams for the two CHP applications mentioned above:

1. Micro-turbine applications require a full Environmental Compliance Approval (ECA);

2. Other solutions such as the use of reciprocating engines are eligible under the Environmental Sector and Activity Registry (EASR) program.

Commercial and Industrial Implication

We have already seen numerous commercial and industrial operations implement co-generation to their Ontario facilities. Generally, these facilities involve manufacturing product, where heat/steam can be used in the manufacturing process, and multi-tenant living or municipal facilities such as recreation or sports complexes. The electricity generated can also be used in their day-to-day operations and excess power can be sold back to the grid. This combination of heat and power is appealing to large, medium and small manufacturing companies.

Current Resources for Involvement and Information

Quality Urban Energy Systems of Tomorrow QUEST is a resource that can help to identify where CHP can be beneficial to your organization. QUEST is the Canadian leader in developing Smart Energy Communities that improve energy efficiency, enhance reliability, cut costs, and reduce greenhouse gas emissions. They are a non-profit organization that conducts research, engagement, and advocacy to advance Smart Energy Communities in Canada.

Through getting involved with QUEST they can help connect you with other government organizations, utilities, the energy industry, the real-estate sector, economic regulators, and the product and professional service sector so you can make the most informed smart energy decision.

Recent posts

-

-

Unlocking value through solar PV repowering: A focus on module replacement and DC/AC optimisation

by David Fernandez

View post -