A Fortune 500 telecommunication company’s circular model to eliminate waste from experiential marketing

- Post Date

- 23 September 2024

- Read Time

- 5 minutes

Tackling waste from trade shows and events

Experiential marketing activations provide a critically important way for businesses and brands to connect with consumers through creative, interactive events and pop-up experiences. But building real-life brand connections often produces environment-damaging waste.

A traditional approach to experiential marketing - including trade shows along with activations at more consumer facing events - uses raw material to create items that are tailored to the event and become waste after a single use. Events generate immense waste, e.g. trade shows alone generate an estimated 600,000 tons of waste/year [1] and an average US college sporting event generates 50-100 tons [2] of waste.

As a sustainability leader with high ambitions for improving environmental impact, this Fortune 500 telecommunications company couldn’t accept the status quo when it came to the waste and resource use that is standard practice for this type of marketing. They worked with SLR to repurpose existing materials that had been kept in storage, diverting them from the waste stream. As a result of that engagement, they diverted 51% of existing waste in 2021.

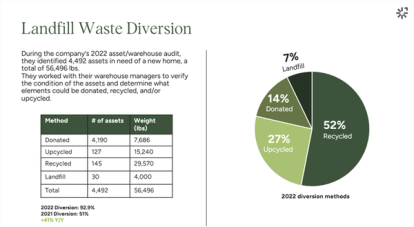

We then developed a circularity plan that ultimately designs waste out of the experiential marketing system. In 2022, the Circularity Action Plan reduced the creation of one-time-use materials, eliminated branding barriers and material barriers to recycling, developed new systems for tracking and reusing modular designs, and increased waste diversion from 51% to 93% at end of life.

Upcycling [3] (taking something no longer in use and giving it a second life and new function) of the remaining plywood from these assets into step stools, accounted for diverting 27% of the waste.

The principles behind long-term change

To ensure the action plan is truly actionable, it had to be fully accessible to those responsible for design, sourcing, fabrication, and asset management across functions – not just sustainability professionals. This meant building from the more general circularity principles typically found in this type of guidance to very clear, specific, direction on exactly what steps each role will take to implement the circularity plan. It also meant that action must be mapped to existing asset management life cycles. Rather than attempting to tack on an additional sustainability action to a long list of responsibilities, this plan integrates fully into current processes and responsibilities. Operationalising this plan requires changes to processes – but does not rely primarily on additions to processes.

First, guiding principles are described in plain language, to be referenced throughout the plan:

- Minimise new material use - Minimise new material use and end-of-life waste by using existing assets and minimising materials used in new asset design.

- Plan for reuse & end-of-life - When a new asset is required, design it so that it can be reused in subsequent activations, and track it between events to make reuse sustainable and accessible.

- Make it recycled and recyclable - Choose more sustainable, recycled materials that are more easily recyclable at end-of-life, especially when one-time use is required.

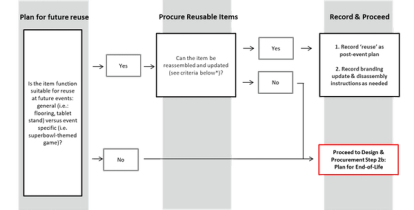

Then, these principles are embedded and direction mapped to each stage of the experiential asset life cycle. The existing responsibilities of each function in that stage are described, with plain language definitions of key terms, step-by-step procedures and decision trees, and criteria for application of the principles that account for potential barriers. For example, one barrier to reuse identified in the review of previously created assets is that branding is frequently updated; items with outdated branding becomes unusable and destined for the waste stream unless the branded elements can be easily updated. So, the design stage now includes planning for reuse or recycling at end of life, and when reuse is planned updatable branding is included in the design criteria.

Criteria for reusable design

- The item is general enough to adapt for different types of events

- The branding can be updated for future use (confirm logos and colour finishes can be updates while maintaining functional and design integrity of the item)

- The item can be easily disassembled for storage and reassembled without damage (conform removable fasteners, breaks down to flat pieces sized for efficient storage)

While we are proud of the amount of existing assets we have already diverted (which were not designed for reuse or diversion) we know that the impact of these redesigned processes will be far greater. This circularity action plan makes experiential marketing more sustainable at the company, it can serve as a blueprint for operationalising circularity in every company that participates in similar activations, regardless of industry – proving that in addition to dramatically reducing the environmental footprint of these marketing and event activities, circular models can be practical, economical, and inspiring.

--------------------------------------

References

[1] https://cleaningbusinesstoday.com/blog/making-this-issas-most-sustainable-trade-show-ever/

[2] https://www.roadrunnerwm.com/blog/stadium-arena-recycling

Recent posts

-

-

-

Understanding sound flanking: Fire alarm speaker cable conduits in multi-family buildings

by Neil Vyas

View post