Occupational noise exposure assessment and mitigation for Blue Spark Energy

- Client Name

- Blue Spark Energy

- Location

- Calgary, Alberta, Canada

Challenge

Blue Spark Energy has developed a hydraulic pulsing down-hole technology for the oil and gas industry featuring an electrode placed inside a well. This electrode releases a powerful hydraulic impulse through an electrical discharge, generating a corresponding impulsive sound. During testing and demonstration activities, there is a potential for both the equipment operator and observers to be exposed to high sound levels. Blue Spark Energy proactively requested an occupational noise exposure assessment to quantify noise exposure risk and provide potential mitigation options to support the well-being of their staff and visitors.

Originally, noise exposure during testing and demonstration activities was managed only through hearing protection. However, hearing protection is not considered a primary noise control measure and should be the last line of defense for worker noise exposure. In high-noise environments, relying solely on hearing protection can unintentionally cause communication and safety issues, such as making alarms less audible. Noise exposure may be more effectively reduced by lowering equipment noise levels at the source and reducing exposure duration than through administrative controls.

Solution

SLR conducted repeatable on-site measurements in collaboration with Blue Spark’s engineering manager and equipment operator to assess noise exposure levels throughout the facility. The noise exposure assessment was conducted based on the standards defined in Alberta’s Occupational Health and Safety Code (AOHSC). Due to the nature of the noise, additional consideration was provided for C-weighted peak sound level requirements which are not accounted for in the AOHSC.

SLR’s assessment found that the maximum allowable exposure time at the nearest observation point to the testing apparatus, to avoid exceeding the AOHSC daily exposure limit of 85 dBA Lex, was approximately 22 minutes. There was a significant risk that if the operator or other workers were exposed to the sound generated by the pulsing events for longer than 22 minutes within a shift (for example, during multiple demonstrations), the AOHSC-prescribed 85 dBA Lex limit could be exceeded.

SLR recommended mitigation options to address this risk. These measures included:

- Increasing the setback distance of the operator position.

- Limiting the time that the operator needs to spend in very close proximity to the test apparatus, such as through camera-controlled inspections or similar.

- Providing an acoustic enclosure or barrier between the test apparatus and the worker.

Impact

In accordance with SLR’s recommendation, a custom acoustic enclosure was procured from and installed by a trusted noise control supplier – Merlin Noise Control. Following the installation of this custom enclosure, SLR returned to conduct a follow-up noise exposure assessment to confirm the reduction in sound levels and review the enclosure construction with the client. After implementation, noise exposure levels within the facility were reduced to well below applicable health and safety limits. With the custom acoustic enclosure, AOHSC limits are not expected to be exceeded for a full day’s shift of exposure time. As a result, workers and observers at Blue Spark Energy are further protected from damaging levels of occupational noise.

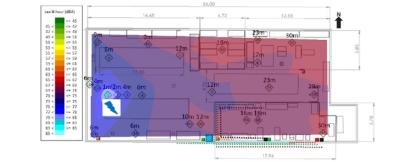

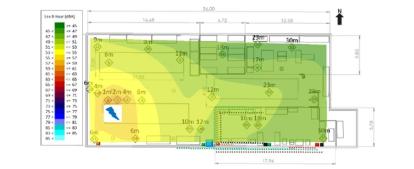

A comparison of approximate mapped noise exposure levels throughout the facility before and after the enclosure installation is shown below.