Part two: Hydrometallurgy, chemical analysis and magnetic separation at SLR’s mineral processing laboratory

by Ben Simpson

View post

This article has been produced to assist developers of SMR and electrolysis hydrogen production facilities to understand the requirements of the Environmental Permitting (England and Wales) Regulations 2016 (as amended) (EPR) and similar legislation in Scotland and Northern Ireland.

In the coming years, the production and use of Hydrogen is going to be a significant contributor to the reduction of carbon emissions, whether it be to fuel HGVs, ships and buses or as a replacement for natural gas to decarbonise heat within industry. For example, refer to SLR’s report on the Decarbonisation of heat across the food and drink manufacturing sector, prepared on behalf of the Food and Drink Federation.

In its Build Back Better: Our Plan for Growth and Ten Point Plan for a Green Industrial Revolution, the UK Government has made it loud and clear that increasing Hydrogen Production capacity alongside Carbon Capture and Storage (CCS) is key to its plan for the transition to Net Zero Carbon emissions by 2050.

In 2019, the UK produced around 27 TWh of hydrogen (Committee on Climate Change, May 2019). By 2050, and to achieve net zero carbon, the National Grid estimates UK hydrogen demand will be between 152 and 591 TWh, i.e. requiring somewhere between a 5 and 22-fold increase in production capacity.

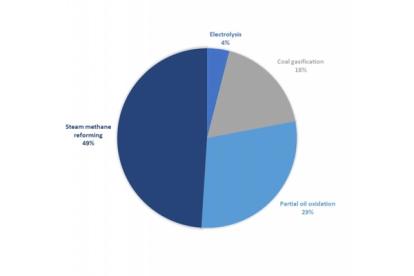

How we produce hydrogen is going to change also. As of 2019, up to 96% of the UK hydrogen production capacity was ‘grey’, being derived from fossil fuels without use of CCS. With only 4% being ‘green’ from the electrolysis of water – see Figure 1. To achieve our net zero ambitions, the focus going forward is on developing green hydrogen by electrolysis and ‘blue’ hydrogen by steam methane reforming (SMR) of natural gas combined with CCS.

Hydrogen production in the UK

The EPR and similar devolved regulations require operators of specified activities to obtain and comply with the conditions of an environmental permit.

Hydrogen production is one such regulated activity being listed in Schedule 1 of the EPR under Section 4.2 Production of inorganic chemicals. Carbon capture for the purposes of geological storage is a regulated activity under Section 6.10 also. Treatment of waste waters and their discharge to the environment are regulated too, if undertaken.

These activities are regulated by the Environment Agency (EA) in England, Natural Resources Wales in Wales, the Scottish Environmental Protection Agency in Scotland and the Northern Ireland Environment Agency in Northern Ireland.

Once obtained the environmental permit will contain conditions on management, operations, emissions & monitoring and record keeping / reporting.

To obtain an environmental permit, operators must make an application to demonstrate they will be able to comply with the conditions of the environmental permit. The application will need to include risk assessments, management plans / procedures and demonstration of the application of Best Available Techniques (BAT). The content of which will depend on the technology employed, the risks associated with it, and the site’s setting.

Low impact installation standard rules environmental permits are available for certain hydrogen production facilities. Standard rules permits are available for a low-risk operations provided they can comply with the fixed set of conditions. The EA has already consulted on and risk assessed these so the application process, costs, and regulatory effort employed is less, compared to a facility requiring a bespoke environmental permit.

To qualify for the standard rules environmental permit (SR2009 No 2), the facility must not:

They must also have contained drainage to prevent emissions escaping to surface water, sewer and land.

Typically, a hydrogen production plant producing less than 2 tonnes per day will be capable of meeting the criteria for a SR 2009 No 2 permit according to the British Compressed Gas Association. Numerous electrolysis-based refuelling stations at research and innovation centres have been permitted under this route for example.

Facilities that are not eligible for the standard rules will require a bespoke environmental permit.

One of the key aspects for applicants to demonstrate is the application of BAT. It is therefore important to consider BAT at the design stage.

At the time of writing, there is not one detailed single guidance document describing BAT for Hydrogen Production and there is a gap in guidance on what constitutes BAT for SMR with CCS. The publication of such guidance is in progress however, with the publication ‘Establishing Best Available Techniques (BAT) for hydrogen production from methane with associated carbon capture and storage (CCS)’ anticipated in 2021.

There are however a number of useful documents to refer to establish BAT for Hydrogen Production in the UK. These include the European Commission’s BAT Reference document for Refining of Mineral Oil and Gas (2015) (in the case of SMR without CCS) and the Manufacture of Large Volume Organic Chemicals Bref (2017) (also SMR without CCS), Production of Chlor-alkali Bref (2014) (for Electrolysis) and the horizontal Common Waste Water and Waste Gas Treatment in the Chemical Sector (2016) (all).

Key issues to be considered during the determination will include the following:

SLR recommends that developers of such facilities consider these matters at the design stage.

SLR’s Environmental Management, Permitting and Compliance team can offer numerous services to Hydrogen Production plant developers and operators and are supported by a range of technical experts. SLR can:

[1] Candidate or Special Area of Conservations (SAC) and proposed or Special Protection Areas (SPA), Sites of Special Scientific Interest (SSSI), Ramsar sites, National Nature Reserves (NNR), Local Nature Reserves (LNR) and Ancient Woodland.