The devil is in the acoustic details: (part one) Metal studs

- Post Date

- 04 May 2022

- Read Time

- 4 minutes

From my experience resolving noise and privacy issues in buildings I have learned that the cause is usually an oversight of seemingly small but absolutely critical details. Details that could have been addressed during design and/or construction to avoid the resulting disruptions to operations and costly remediation.

In this first instalment of our series on the devils that lie in acoustic details, I discuss two important decisions for metal stud acoustic wall assemblies: the stud gauge and the stud spacing. Choices made around these two parameters can dramatically affect the Sound Transmission Class (STC) rating and sound isolation performance of a partition.

The Effect of Stud Gauge

Metal studs are typically used in commercial construction because they are inflammable, hold their shape (i.e., don’t warp), and are handy for routing of services (i.e., electrical, plumbing etc.). They are usually specified by gauge number, which relates to the design thickness of the stud. For example, a 25 gauge stud has a design thickness of 18 mil, a 20 gauge stud has a design thickness of 30 mil, and a 16 gauge stud has a design thickness of 54 mil. The choice of a particular gauge for a wall assembly is normally determined based on a few criteria:

- structural deflection limits for the project (max allowable out-of-plane displacement of the wall subject to lateral loading);

- span length (floor-to-floor height); and,

- ability to resist abuse.

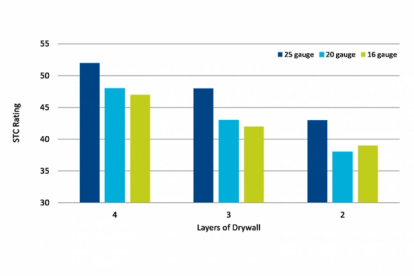

So what are the implications of stud gauge selection on sound transmission loss and the STC rating of the wall? Figure 1 summarizes the results from a 2010 study in which several metal stud wall assemblies were tested to investigate the effects of stud gauge on STC rating[1]. Three sets of walls, with three differing numbers of drywall layers were tested. All walls had the same stud spacing and stud depth and only stud gauge was varied.

The results from the testing indicate that substitution of 25 gauge studs with 20 gauge or 16 gauge can result in a four-to-six point reduction in STC rating.

It is worth mentioning here that the majority of published test data and ratings are based on wall assemblies constructed using 25 gauge studs.

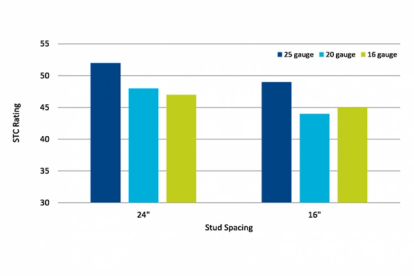

The Effect of Stud Spacing

The spacing of studs also affects the stiffness of the wall assembly and has a similar, though less drastic, effect on STC rating. Figure 2 summarizes the results from the same study for a series of tests conducted with varying stud spacing while holding all other parameters constant (stud gauge and depth, layers of drywall etc.). In this case, the increase in wall stiffness due to a drop in stud spacing from 24- inches to 16-inches can result in a two-to-four point reduction in STC rating.

The test results paint a pretty clear picture of how the choice of stud gauge and spacing will affect the STC rating of your wall. All else being equal, if you are required to reduce the stud gauge from 25 to 20 and the spacing from 24-inches to 16-inches, the STC rating could be reduced by up to ten points. From the perspective of the occupants and end users, this could mean up to ten more decibels of sound transmission through the wall and a perceived doubling of the transmitted sound level. It could mean the difference between muffled, unintelligible speech and clearly perceptible conversations.

Putting your Wall Together

Establishing the structural requirements should be the first step in the design process. The second step is to optimize wall thickness (impact on net floor area), and cost while satisfying acoustic requirements. This is where things can get a little more challenging.

Consider the following common strategies to improving STC ratings:

- increasing stud width (e.g., swapping 3-5/8” studs for 6-inch studs);

- adding layers of drywall;

- moving to a double-stud (cavity wall) assembly;

- using specialty drywall; and,

- using acoustic framing elements such as resilient channels or isolation clips.

These approaches can all increase the STC rating (some more than others), but may remove usable floor area, may reduce durability and may add material and labor costs to the project. The ramifications can be significant on very large and complex buildings like healthcare and education facilities.

Parting Thoughts

From the above discussion we can assemble some key takeaways to consider for your next project:

- Be sure to verify wall deflection requirements with the structural engineer early on. This forms the foundation for design of metal stud acoustic assemblies.

- Include both the stud gauge and spacing on your partition schedules to ensure what gets built is consistent with the design.

- Remember: stiffer studs and shorter stud spacing means a lower STC rating!

Stay tuned for future posts in this series where we discuss more of the devils in acoustic details.

Reference:

[1] Betit, A. (2010) Performance details of metal stud partitions, Sound & Vibration, March 2010.

Recent posts

-

-

Unlocking value through solar PV repowering: A focus on module replacement and DC/AC optimisation

by David Fernandez

View post -